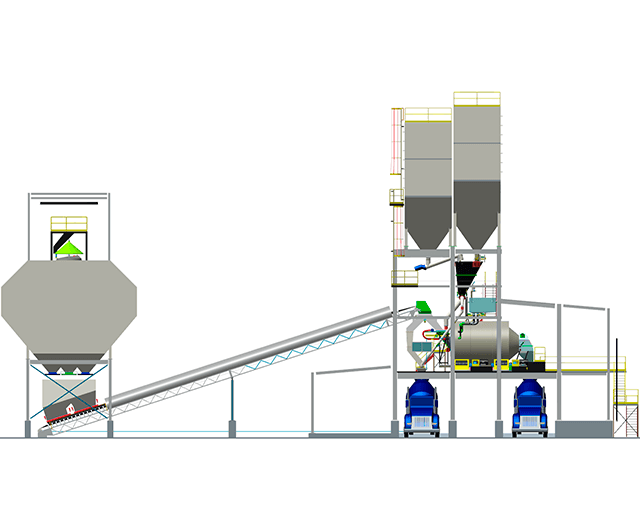

BMH Custom Series

Overview

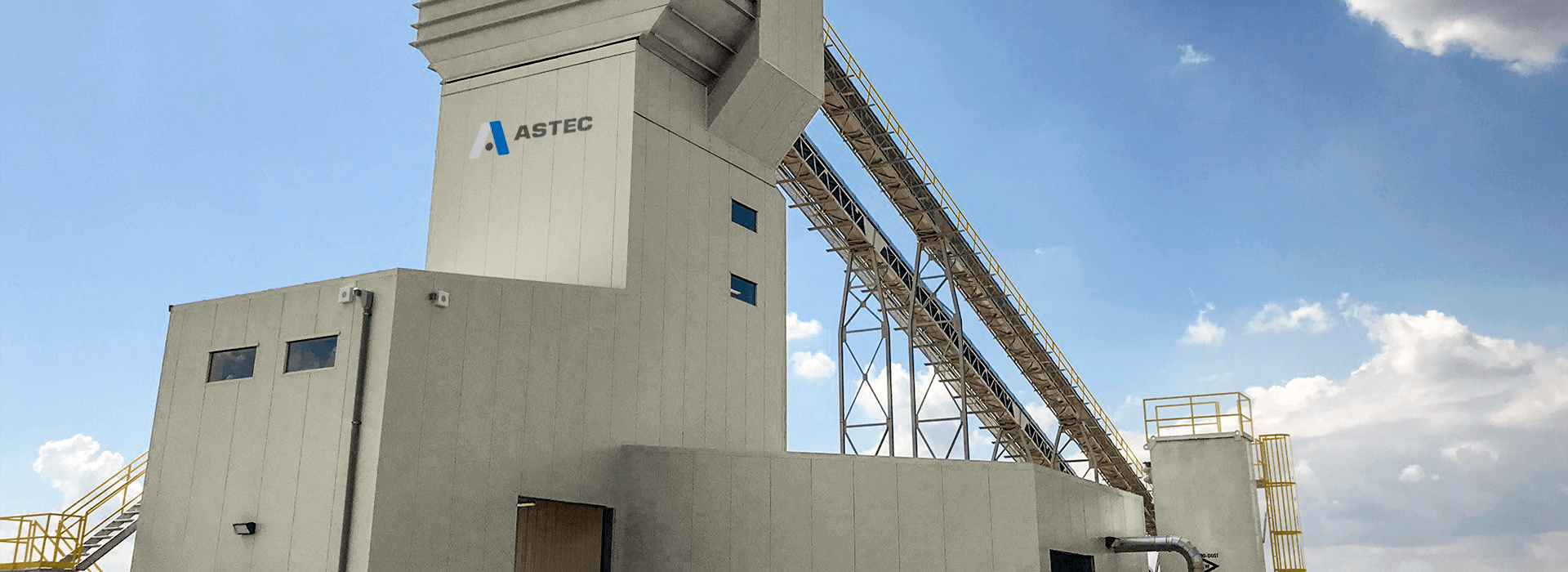

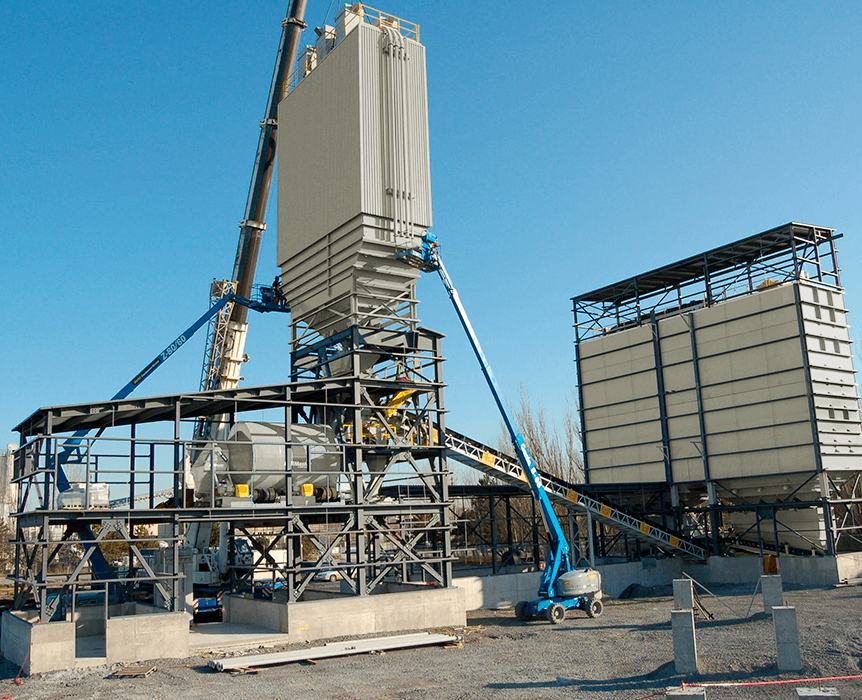

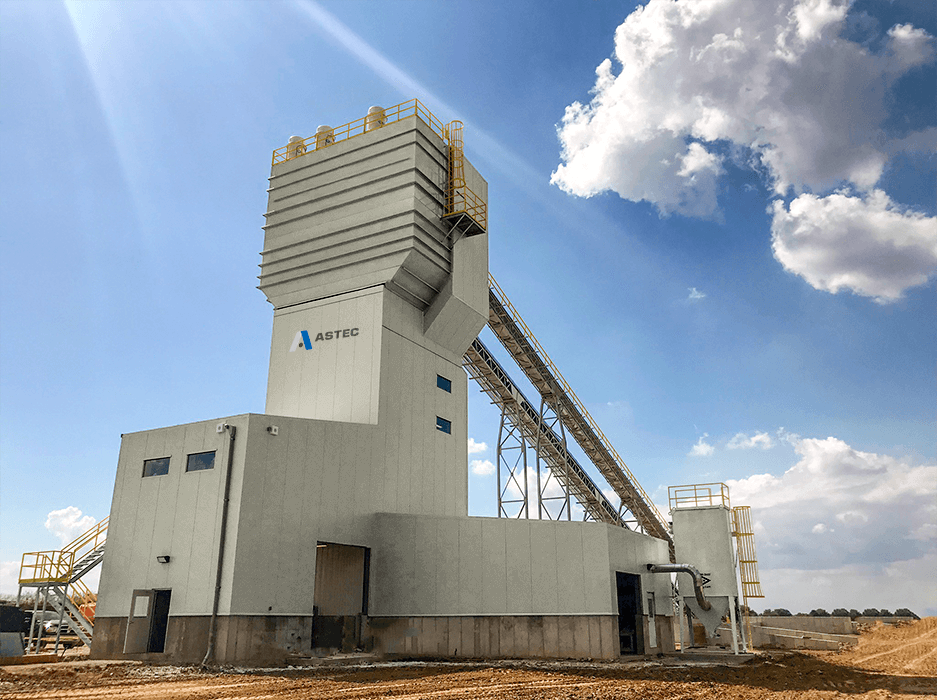

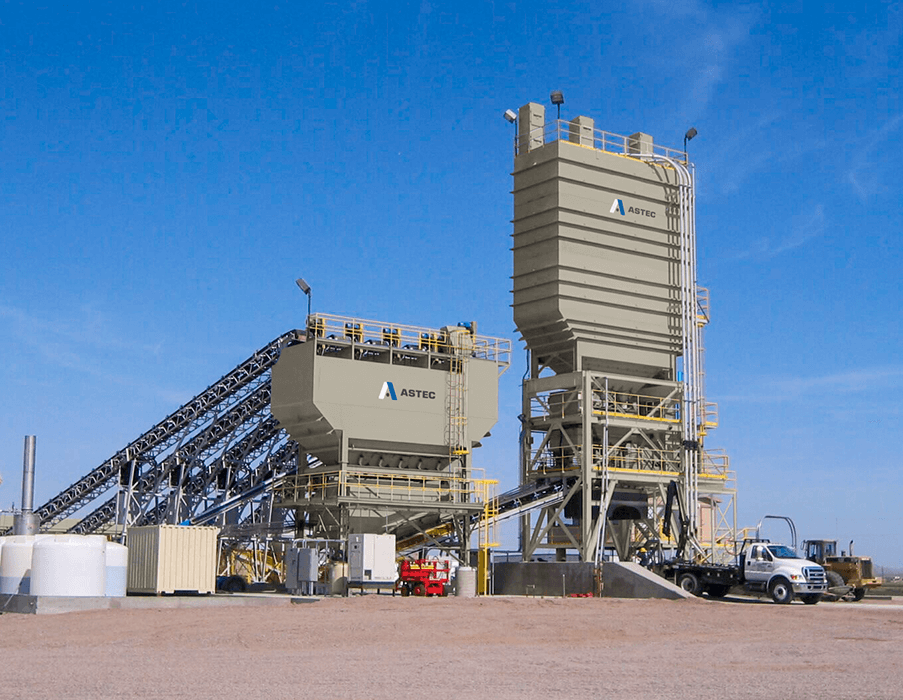

Complying with today’s rapid evolution of concrete applications requires flexible and reliable plants. From the modernization of existing plants to the construction of brand new facilities, each project is based on a thorough analysis of the client’s individual needs. Astec provides a one stop shopping opportunity for its customers. From the design stage to the commissioning of a concrete batch plant, Astec directly manages each step of the project through a modular and integrated approach within a structure that is ISO 9001-2015 certified.

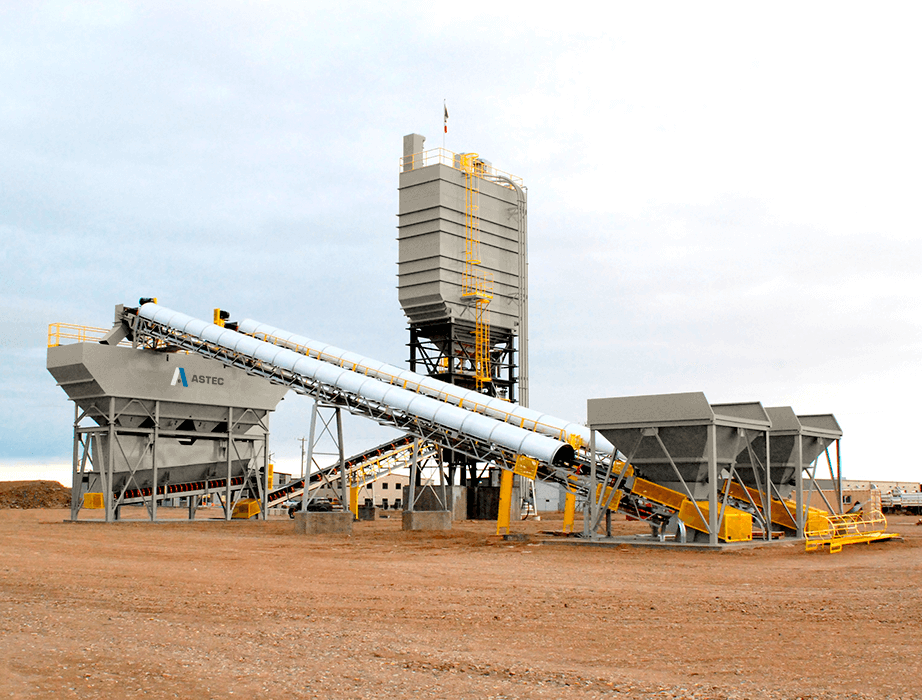

Astec manufactures reliable stationary dry/transit mix and wet /central mix batch plants, ranging from 120 to 240 yd3/hr (50 m³ to 183 m³/hr), to meet your particular production needs. Our stationary models (LP-8, LP-9) and our high production large capacity plants are tailored to meet your needs.

Applications

-

![Astec BMH EG Dry Batch Concrete Plant]()

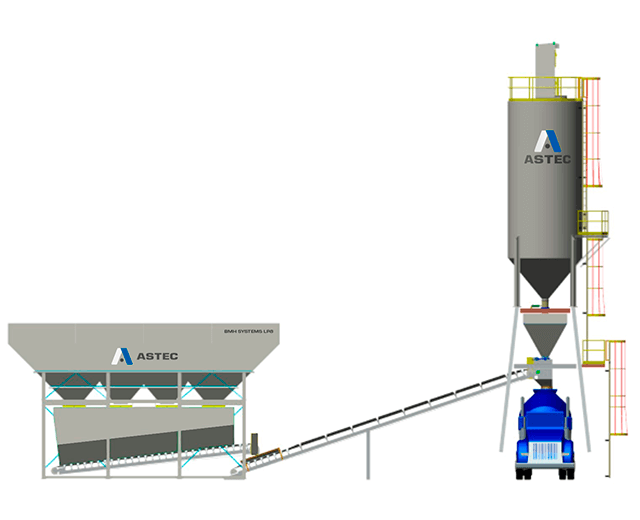

Ready Mix Concrete

Learn MoreMany plants in Astec's extensive concrete product line are well-suited to ready mix operations.

-

![]()

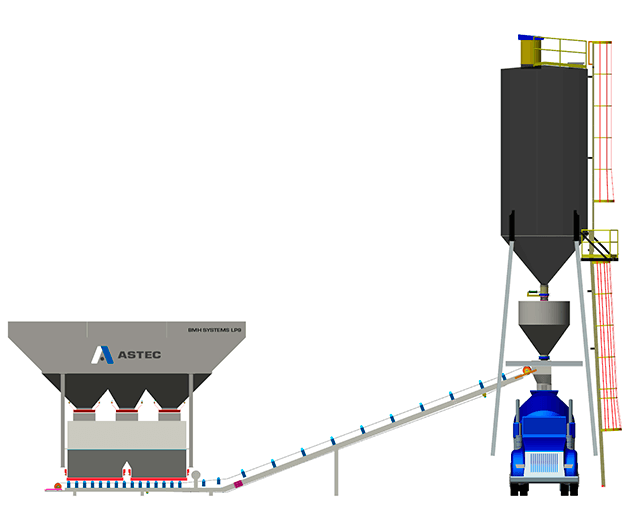

Specialty Concrete

Learn MoreNo matter what the application, with an industry-leading concrete product line Astec is ready to help you build a plant to meet your needs.

-

![Astec BMH custom concrete plant for the precast industry]()

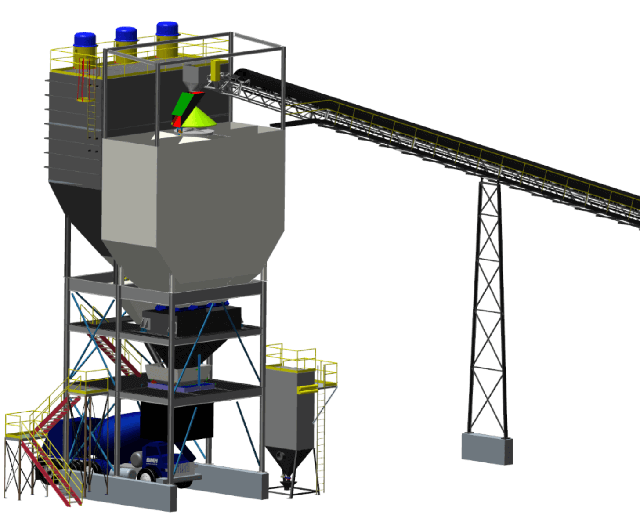

Precast & Prestress

Astec's comprehensive concrete product line features many plants and components for the precast/prestressed concrete market.Learn More

Downloads

Key Specifications

All specifications subject to change without notice.